Semi-automatic big-bag filling systems, based on NET or GROSS weighing method. The systems are individually designed, depending on the type of big-bag and product.

Contact us for more information, to select the correct system for your production.

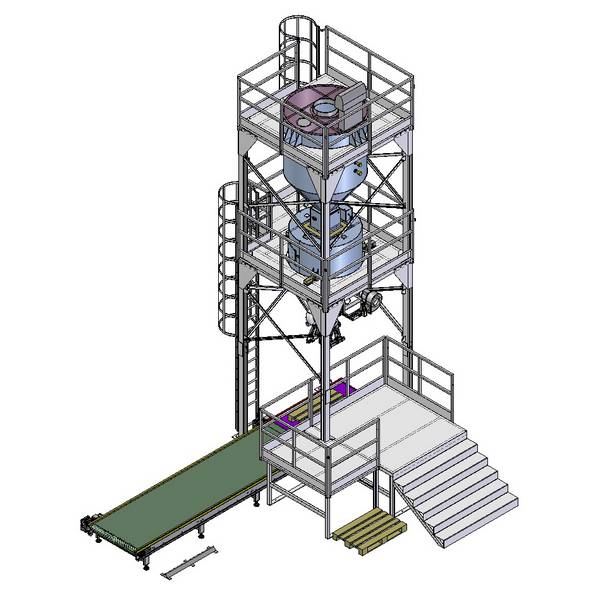

Description:

- Filling machines for big-bags with net weight dosing system for flowing products.

- Manual positioning of the empty big-bag.

- Automatic evacuation of the full big-bag.

- Gravity feeder.

- Accessories:

- - Lifting device (for different big-bag heights)

- - Loops anchoring device (2 or 4)

- Type of bag: 2 or 4 loops with or without collar, single bag

- Weighing range: 500-1500 kg

- Production speed: up to 80 bags/h

Description:

- Filling machines for big-bags with gross weight dosing system.

- Manual positioning of the empty big-bag.

- Automatic unhooking and automatic evacuation of the full big-bag.

- Different feeding systems are available, according to the kind of product to be packed:

- BBL-SC Single screw feeder (powder products)

- BBL-DC Double screw feeder (powder products)

- BBL-N Belt feeder (low flowability products)

- BBL-G Gravity feeder (granular products)

- Accessories:

- - Lifting device (for different big-bag heights)

- Type of bag: 2 or 4 loops

- Weighing range: 500-1500 kg

- Production speed: up to 30 bags/hour