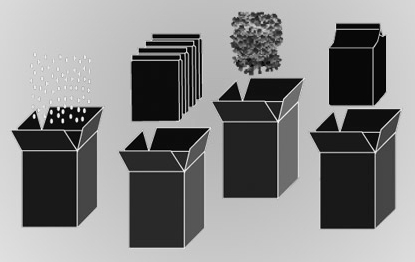

Vertical carton filling machines from BETTI. With over 50 years of activity, the BETTI machines are reliable and respected throughout the world in several sectors, for all products which can be packed in cartons. A selection of their product range is shown below. Please contact us for more information.

Description:

Suitable for meeting the needs of customers who do not require high-speed production. Versatile, reliable, strong and reasonably priced. Suitable for packing granular products, powders, pasta, etc., with volumetric dosing or electronic weighers. This cartoner efficiently solves the problems of companies needing to pack numerous types of cartons because size-groups can be quickly changed even by non-skilled staff. Ease of use and a sturdy structure have made this a highly regarded machine for over 40 years. Now updated with the very latest technological innovations, it provides reliable, top-quality packaging.

Operation:

Flat cartons are loaded on the blanks magazine and automatically conveyed to the forming system. Once in the machine, the cartons undergo marking on the outside flap, gluing and bottom closure, before reaching the filling area.

Filling is done using the system most suitable for the Customer's product.

The carton is then glued and sealed on top before being conveyed to the outfeed conveyor.

It is also complete with:

- Production speed adjustment with electronic system.

- Size changeover adjustment.

- Continual regulation of product weight and volume.

- Production and feed automatic devices.

- Electronic unit for programming and storing gluing parameters and other automation parameters.

- Full accident-prevention protection in compliance with the law and CE mark.

Description:

It is the most versatile cartoning machine of our production line, since it allows the packaging of a wide range of cartons, special cartons included. It is suitable for several types of products, since it can be supplied with different filling units and specific modular equipments. The machine can be supplied with a volumetric telescopic cylinders dosing device, auger filler, electronic weighers and unit counters, or otherwise be supplied with units for the automatic introduction of vacuum or pillow bags and carrousels introducing solids, such as bottles, glasses, car filters and similar products.The machine can be supplied with more modules, thus allowing the selection either of the continuous or step by step motion,according to the working requirements. Furthermore, standard, labyrinth, van-buuren or tuck-in closing cartons, with glued or thermo-welding sealed inner lining can be used; special cartons might as well be used. A state-of-the-art technology and a continuous updating, make this basic machine, manufactered for over 35 years, suitable for meeting the most demanding market requirements.

Operation:

The flat cartons are loaded on the blanks magazine and automatically conveyed to the forming up system. The cartons, once in the machine, undergo marking on the outside flap, glueing and closure of the bottom, before reaching the filling zone. Filling is carried out with a system suitable for the client's product. This is also a machine that lends itself to special uses; before upper glueing particular structures may be mounted: loaders, dispensers, labeling machines, special markers, etc. The carton carries on to be glued and to be closed for good on the upper side an finally transferred to the out-put conveyor.

It is also complete with:

- Regulation of production speed with electronic system.

- Size change adjustments.

- Adjustments of product weight or volume.

- Automatism and checking of production and feeding.

- Electronic device controlling the glue application.

- Autolubricating cartons transporting system.

- Accident prevention protections of integral type as according to law with CE mark.

Description:

This belongs to a series of cartoning machines of medium production speed for small and medium cartons. Suitable for packing granular products, powders, pasta and others by volumetric dosings or electronic weighers. It may be equipped for the packing of single or in groups bags, bottles, etc. This smartly resolves the problems of those companies that have to pack numerous types of cartons in that the format change-over is done in a few minutes without the need for specialized staff. Simplicity and a robust structure have permitted to be highly regarded for more than 30 years. The continuous technological updating with the most recent technical innovations grant secure packaging and the best quality.

Operation:

The flat cartons are loaded on the blanks magazine and automatically conveyed to the forming up system. The cartons, once in the machine, undergo marking on the outside flap, glueing and closure of the bottom, before reaching the filling zone. Filling is carried out with a system suitable for the client's product. The carton carries on to be glued and to be closed for good on the upper side and finally transferred to the way-out line. It is also complete with:

- Regulation of production speed with electronic system.

- Size change regulation.

- Automaticl regulation of product weight or volume.

- Automatism and checking of production and feeding.

- Electronic device controlling the glue application.

- Accident prevention protections as according to law with CE mark.

Description:

A cartoning machine of truly modern conception. It incorporates all the very latest electronic and mechanical features to satisfy the increasingly more sophisticated requirements of production and markets. After undergoing various changes and updates during its 30 years of production, the most sophisticated and modern version of technological machine is now available. The NB/150/36 model is equipped for filling by volumetric dosing and hot-melt gluing with multi-line application. It's also equipped with a space for coupon dispensers. This model (and other similar versions) is designed to package powdery, granulated and similar flowing products. Using optional equipment, the same basic model can also pack glasses and bottles of different sizes, including into luxury cartons. The NB/150/26 model works perfectly with computerised multi-electronic weighing machines. This model was developed specifically for packaging pasta and breakable, granulated or special products without damaging or deteriorating them. At the same time, thanks to our exclusive system, weighing machine potentialities have been optimised in order to avoid empty cartons at even the highest production speeds. The NB/150/28 model can be equipped with cold gluing with automatic feed. Our extensive experience in this field enables us to present a cutting-edge machine incorporating all those features that have made our company respected worldwide: structural solidity, ease of mantenance and practical size changeover.

Operation:

The flat cartons are placed on the blanks magazine and automatically conveyed to the forming system. Once in the machine, the cartons undergo marking on the outside flap, gluing and closure of the bottom before reaching the filling area. Product dosing can be done by means of a telescopic-cylinder volumetric system, weighing units, etc. The carton is

then glued on the upper side and finally transferred to the way-out line. It is also complete with:

- Production speed adjustment with electronic system.

- Size changeover adjustment.

- Continual regulation of product weight and volume.

- Infeed automatic control and production data store.

- Dust extraction nozzles, devices, vibrator and specific devices suitable for the product.

- Electronic glue application control.

- Full accident-prevention protection in compliance with the law with CE mark.

Description:

To meet continually higher production needs, a set of highspeed cartoning machines has been produced, able to also cater for the request of the most discerning customers. Equipped with all the electronic controls to guarantee high quality production. Made using mechanical component parts that permit running the machine for long periods without special maintenance. Suitable for packing granular and powdered products by means of cylindric volumetric doser or if linked to multiheads computerized weighers, packing products of different grain size, pasta and similar products. We also produce models for packing bottles, small glasses, filters and other solids.

Operation:

The flat cartons are placed on the blanks magazine and automatically conveyed to the forming system. Once in the machine, the cartons undergo marking on the outside flap, gluing and closure of the bottom before reaching the filling area. Product dosing can be done by means of a telescopic-cylinder volumetric system, weighing units, etc. The carton is

then glued on the upper side and finally transferred to the way-out line. It is also complete with:

- Production speed adjustment with electronic system.

- Size changeover adjustment.

- Continual regulation of product weight and volume.

- Infeed automatic control and production data store.

- Dust extraction nozzles, devices, vibrator and specific devices suitable for the product.

- Electronic glue application control.

- Full accident-prevention protection in compliance with the law with CE mark.