Vertikale kartonfyldemaskiner fra BETTI. Med over 50 års erfaring, er BETTI maskinerne pålidelige og respekteret over hele verden i flere sektorer, til alle produkter, der kan pakkes i kartoner. Et udvalg af deres maskiner ses nedenfor. Venligst kontakt os for yderligere information.

BETTI NB150

Description:

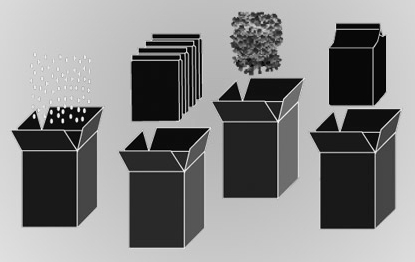

A cartoning machine of truly modern conception. It incorporates all the very latest electronic and mechanical features to satisfy the increasingly more sophisticated requirements of production and markets. After undergoing various changes and updates during its 30 years of production, the most sophisticated and modern version of technological machine is now available. The NB/150/36 model is equipped for filling by volumetric dosing and hot-melt gluing with multi-line application. It's also equipped with a space for coupon dispensers. This model (and other similar versions) is designed to package powdery, granulated and similar flowing products. Using optional equipment, the same basic model can also pack glasses and bottles of different sizes, including into luxury cartons. The NB/150/26 model works perfectly with computerised multi-electronic weighing machines. This model was developed specifically for packaging pasta and breakable, granulated or special products without damaging or deteriorating them. At the same time, thanks to our exclusive system, weighing machine potentialities have been optimised in order to avoid empty cartons at even the highest production speeds. The NB/150/28 model can be equipped with cold gluing with automatic feed. Our extensive experience in this field enables us to present a cutting-edge machine incorporating all those features that have made our company respected worldwide: structural solidity, ease of mantenance and practical size changeover.

Operation:

The flat cartons are placed on the blanks magazine and automatically conveyed to the forming system. Once in the machine, the cartons undergo marking on the outside flap, gluing and closure of the bottom before reaching the filling area. Product dosing can be done by means of a telescopic-cylinder volumetric system, weighing units, etc. The carton is

then glued on the upper side and finally transferred to the way-out line. It is also complete with:

- Production speed adjustment with electronic system.

- Size changeover adjustment.

- Continual regulation of product weight and volume.

- Infeed automatic control and production data store.

- Dust extraction nozzles, devices, vibrator and specific devices suitable for the product.

- Electronic glue application control.

- Full accident-prevention protection in compliance with the law with CE mark.